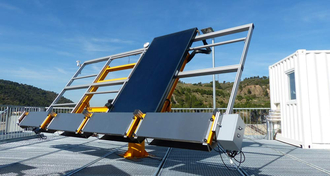

SysColl

Factory made system and collector testing facility

For certification in many markets, performance of the complete factory made system (for example thermosiphon systems) plays an equally important role as collector performance.

Our SysColl test stand is a combined test facility for performance testing of both solar collectors and solar thermal systems. This allows you to take advantage of a flexible two in one test solution.

The entire test facility is constructed in our factory in Germany and shipped ready-for-testing to customers around the world. If a suitable building is not available, we offer a standalone solution installed in an air conditioned container.

Technical specifications

| Simultaneous testing capacity | up to 4 |

| Special collector testing specifications | |

| Accuracy of test conditions | |

| Temporal stability of water temperature | ± 0,1 K |

| Temporal stability of mass flow | ± 1 % |

| Standard boundary conditions | |

| Mass flow | 100 – 600 kg/h |

| Collector inlet temperature variation | 10 – 100 °C |

| Relevant standards |

ISO 9806, EN 12975, ASHREA 93, ISO 9459-5, EN 12976-2 |

Key facts

- Steady state collector testing in combination with our tracking system for the determination of biaxial IAM

- Quasi dynamic collector testing of flat plate and vacuum tube collectors

- Thermosiphon system, forced circulation system and integrated storage collector testing

- Simulation of auxiliary heaters for forced circulation systems

- Testing independent of fresh and cooling water

- Testing of pressurized and non-pressurized systems

- Ready to use and ready for accreditation

- All sensors included

- Configuration from 1 to 4 test circuits in parallel

- Upgrade for storage testing available

For more than ten years we have been building performance test stands for solar thermal applications. Our know-how in user friendliness, certification and accreditation is combined and provided in the control software of our SysColl test bench.

Software features

- Fully automated and manual configuration

- Visualization of the measurement data in a system diagram

- Easy implantation of new sensors

- Generation of raw data and processed data

- Easy traceability of the calibration factors used in the measurement data

- Loading and setting of pre-defined test schedules

© PSE Instruments GmbH 2024