DPT– Drop Tester

Our drop tester is designed to perform drop tests on batteries or other components.

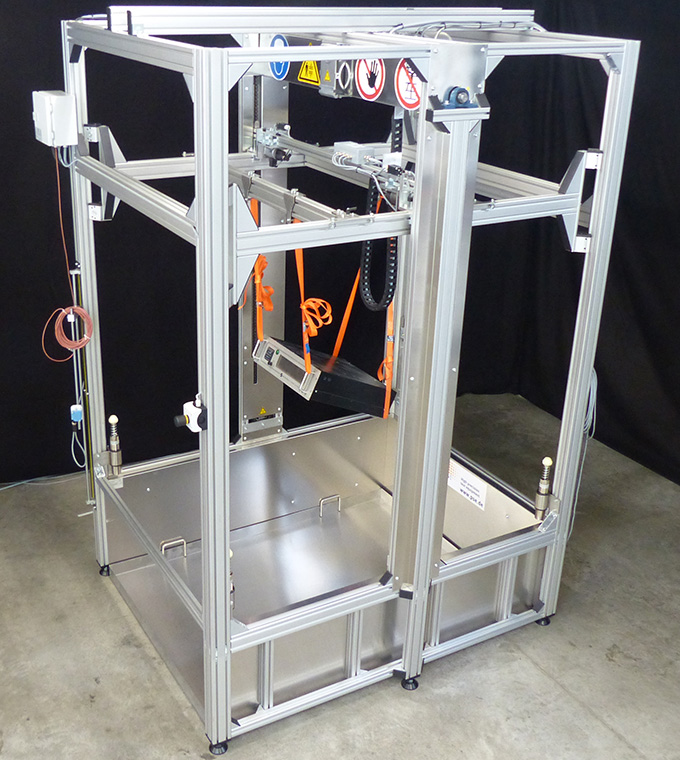

The drop tester comprises a rigid frame for lifting the test object to the drop height, which can be adjusted electrically. A signal lamp at the control board indicates that the drop height has been reached.

Two belts are used to adjust the initial drop angle for the test, whereby the rigid frame guarantees that the object falls in a controlled position. The frame is connected to the lifting mechanism by two electronic magnets. By interruption, the power supply of the magnets a simultaneous release is triggered without any delay. The maximum weight of the device under test (DUT) is 100 kg.

The built-in collecting pan will collect liquids coming out of the test object.

The drop tester is designed to perform the following tests according to VDE-2510-50:2017-05:

- Plane drop test

- Edge and angle drop test

Technical specifications

| Maximum length DUT | 1500 mm |

| Maximum width DUT | 1200 mm |

| Maximum height DUT | 800 – 1000mm (depending on length / width ratio) |

| Maximum weight DUT | 100 kg |

| Relevant standards | VDE-251-50 :2017 :05 |

Key Facts

- Manual remote control or option with automation package

- Precise adjustment of test height

- Flexible design for different test object shapes

- Up to 100 kg test objects

Optional: Software features

- Intuitive graphical user interface for full remote control of the test stand

- Automatic adjustment and measurement of the test height

- Temperature measurement of the test object

© PSE Instruments GmbH 2024